Elevator World Project of the Year Winner! Star Elevator Modernization of The Metropolis Trust Building

LOCATION

625 Market Street, San Francisco, CA

YEAR BUILT

Early 1907, after The Great 1906 San Francisco Earthquake.

CHALLENGE

Untangle a perplexing criss-cross cable-designed gearless basement traction elevator system from the early 20th century and convert it into a modern, overhead traction variable frequency-controlled AC gearless system.

SOLUTION

Completely re-engineer the existing offset basement design. Replace with overhead, modern, compact, energy-efficient, gearless AC machines, counterweights, and rails. Install microprocessor AC (VVVF/AC drives and controllers.

Elevator World Project of the Year Winner, for elevator modernization!

San Francisco in 1907. The City is still shaken from the aftermath of one of the most significant earthquakes of all time. However, The City is surging back to life; rising from the rubble. New building projects are in motion – modern structures will soon line Market Street.

Today, The Metropolis Trust Building sits amongst the most expensive real estate in San Francisco. 625 Market is a designated Category 1 Historic Landmark with a vertical transportation system still anchored in the past –a retrofit of machinery installed over 100 years ago.

21st century safety concerns meet turn-of-the-century building techniques. And there’s no app to solve this one. The elevator systems were all operating well beyond their expected life.

Situation

Project parameters included upgrading the rail systems to bring them up to modern seismic code. New pushbutton and signal fixtures, and modern cab interiors would also be added.

Elevators were not operating reliably –

issues with machine bearings and motor commutators kept cars out of service. In fact, car #1 had been intentionally disabled due to reliability concerns.

Building Management was intent on tenant satisfaction, safe operation, and improved structural integrity, as the historic building approached its second century of operation.

Enter Star Elevator. Despite the project’s inherent complexity, the team was not afraid to roll up its sleeves to solve the 15-story challenge.

The criss-cross crisis

First order of business was untangling the tricks of 1907 tradesmen – including a confounding criss-cross cable system.

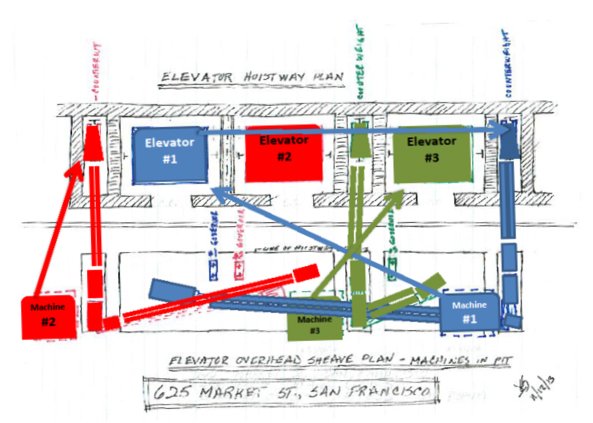

This sketch created by John Sellen of JE Sellen Consulting illustrates the unique challenge of this project.

The elevators had a very unique roping configuration. Due to the placement of the machines under the hoistways, and the need for proper rope lead off of the overhead sheaves, the counterweights did not run in the same hoistways as the cars. This makes for a long, complicated rope scheme – each car had over ¾ of a mile of hoistrope!

Unique original roping configuration

Confounding original criss-cross cable system.

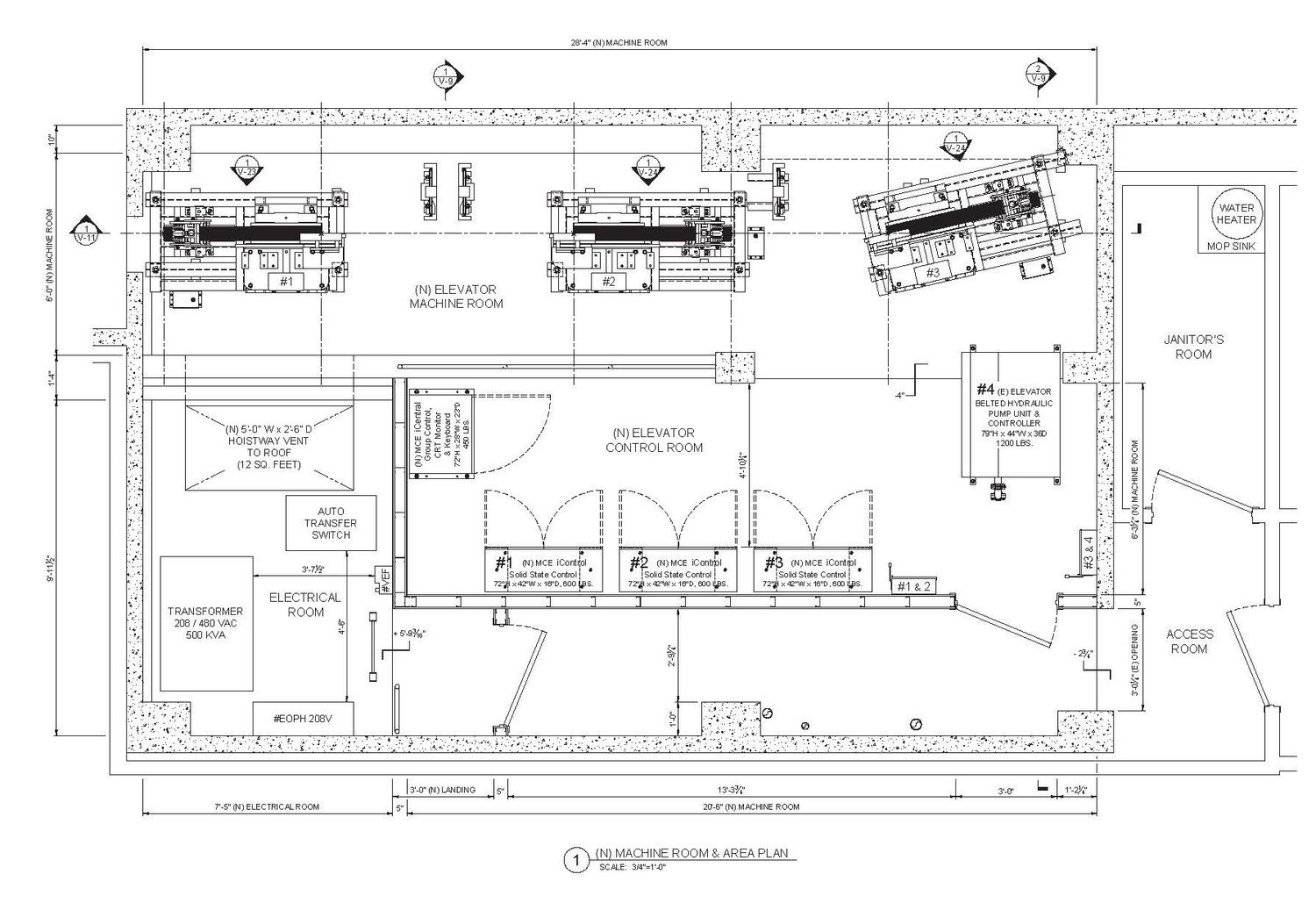

To further complicate matters, there were no building blueprints available. So the team turned to Rich Blaska from RCB Elevator Consulting, LLC. to draw up a detailed plan for everyone to follow.

Design drawings by Rich Blaska of RCB Elevator Consulting, LLC.

Execution

The focus was on job sequencing and scheduling. It was important to keep the building in operation, and keep an elevator running reliably and safely at all times.

Due to the unique rope configuration, it was necessary to shut down two cars at the same time. One car would have to service the building for months, before a modernized car was completed and returned to use.

Every step of the modernization process was a challenge. The Metropolis Trust Building is located on one of the busiest corners in San Francisco; so there was no chance to use cranes. And the building itself offered limited access; there was no loading dock or service entrance. All equipment had to enter through the front door – including 20’ pieces of reinforcing steel and 4,000 lb gearless hoist machines.

Hoisting new equipment up through elevator hoistways because of limited access.

The cabs themselves were disassembled to provide a platform so that the hoist machines could be brought up through the existing hoistways. The machines were set in position 40 inches above the deck in order to achieve the proper traction angle on the drive sheaves.

Outcome

The elevators are now in standard configuration. The new machines are overhead traction and the counterweights run in the same hoistway as the cars. This layout offers improved long-term safety, reliability, and system serviceability.

Cost Savings / Efficiency

Power consumption is down 45% - 50% annually.

Performance Improvements

The new system eliminates three AC / DC converters.

This modernized configuration offers improved speed, long-term safety, reliability, and serviceability of the

system and a significant energy savings.

Elevator World Project of the Year Winner!